KNITTED MESH

Precision in Filtration And Absorption Solutions

Knitted Mesh

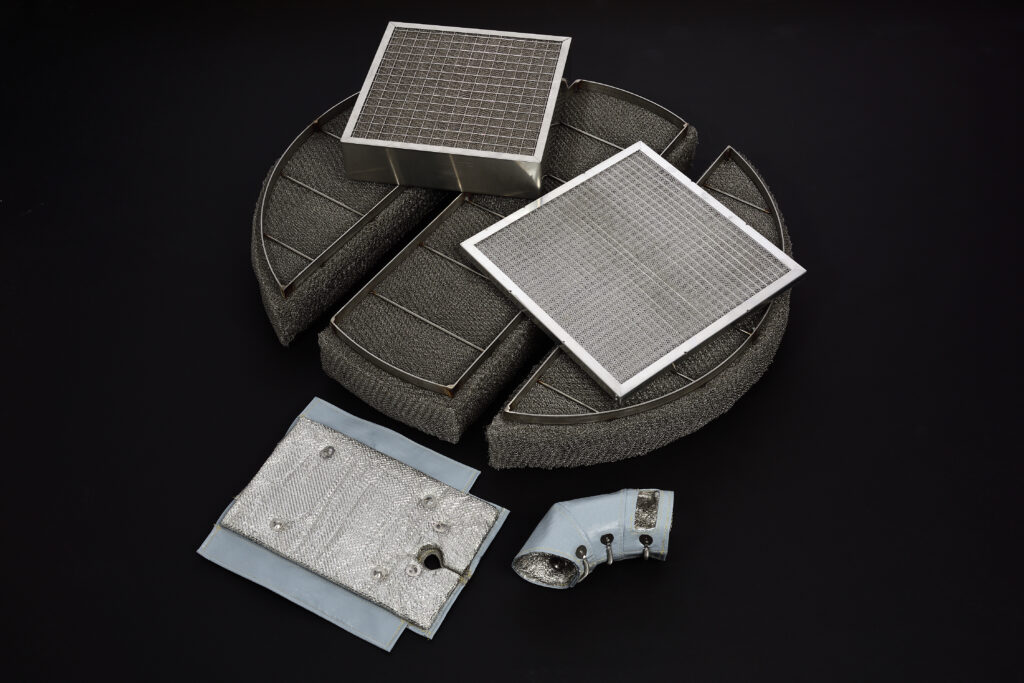

Gasolve offers high-performance knitted mesh solutions designed for a wide range of industrial applications where mechanical strength, flexibility, and efficiency are critical. Manufactured from continuous metal wire or synthetic fibers, knitted mesh is formed into an interlocking loop structure that delivers both resilience and uniform performance across different environments and operating conditions.

What is Knitted Mesh?

Knitted mesh is a wire or fiber-based structure made using specialized knitting machines that produce a mesh with excellent strength-to-weight ratio and high surface area. Unlike woven mesh, the knitted pattern allows it to compress, expand, or be layered into different densities and shapes, making it highly adaptable for demanding process applications.

Common Applications:

Knitted mesh is used across multiple industries, serving both as a core filtration medium and as a support component in complex systems. Key applications include:

Filtration and Separation

Mist Eliminators & Demisters

Noise & Vibration Absorption

Oil & Gas: Used in gas scrubbers, demisters, and coalescing filters to remove fine liquid droplets or solid contaminants from gas and vapor streams.

Chemical Processing: Supports fine filtration in reactive or corrosive environments, especially where multi-layered or structured mesh is required.

Food & Beverage: Provides sanitary filtration solutions for steam or gas cleaning in production lines, especially where metal-free options are needed.

Pharmaceutical: Used in sterile environments for air/gas filtration and fluid separation without compromising product integrity.

Knitted mesh is the core component in mesh pad mist eliminators, designed to remove entrained liquid droplets from gas or vapor flows. These pads are highly effective in reducing carryover losses, protecting downstream equipment, and improving product quality.

Mist eliminators are widely used in vertical and horizontal vessels, scrubbers, absorbers, and separators where controlling liquid entrainment is critical. The knitted mesh is selected based on process parameters such as droplet size distribution, vapor velocity, allowable pressure drop, and separation efficiency.

Knitted mesh is also used as an effective material for damping vibration and reducing mechanical noise. Its spring-like structure allows it to absorb energy, cushion impacts, and isolate components from dynamic loads, making it especially suitable for systems subject to thermal expansion, flow-induced vibration, or pulsating pressures.

In rotating machinery or compressor skids, mesh inserts are used under mounting points or inside housings to reduce resonance and improve stability. Unlike rigid damping materials, knitted mesh retains its form and effectiveness under high temperatures and repeated loading cycles.

Materials and Customisation:

Gasolve offers knitted mesh in a range of materials to suit process-specific needs. Mesh density, wire diameter, strand width, and geometry can all be customised based on application requirements such as particle size, pressure drop limits, chemical compatibility, and mechanical load.